Quality Control

TESTING LAB

All Products are produced in its won foundry and manufacturing bases, under an active and operative quality management system certified by ISO 9001: 2015. In acknowledgment of one-stop lean production from casting to finishing. We have modern technology and also strict technical specifications and a complete quality control procedure. In our company, every single product is completely qualified by a standard instrument and equipment.

Software Based Sand Testing Lab

Our Sand Lab Consists of Below Equipments

- Digital Compactibility Tester

- Digital Moisture tester

- Digital Compressive Tester

- Digital Permeability Tester

- Wet Tensile Tester

- Sieve Shaker

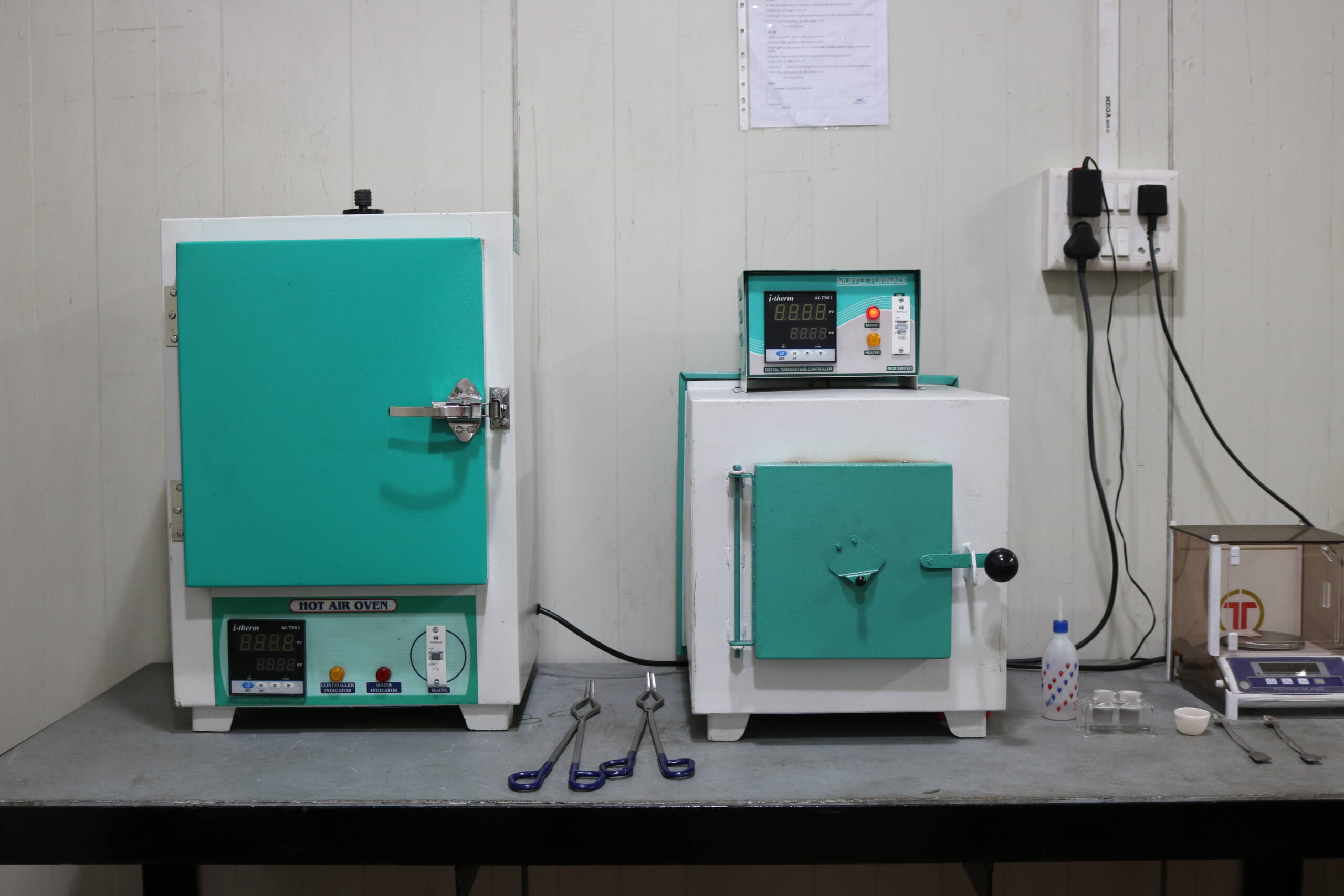

Detailed Sand Testing Lab

- To check detailed parameter of sand, Our inhouse lab

- consists measuring equipment's as per below

- Muffle Furnace

- Heat wave Oven

- Rapid Dryer

- Methylene Blue Value Tester

Contact us to get all your queries solve.

METAL TESTING FACILITIES

UNIVERSAL TESTING MACHINE

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength, elongation and compressive strength of materials.

M.P.I TEST MACHINE

Magnetic particle Inspection (MPI) is a non destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part.

VACUUM EMISSION SPECTROMETER

Optical emission spectrometry involves applying electrical energy in the form of spark generated between an electrode and a metal sample, whereby the vaporized atoms are brought to a high energy state within a so-called “discharge plasma”. For chemical testing (21 elements).

ROCKWELL HARDNESS TESTER

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload

CE METER

Principal of Operation: Thermal Analysis is the interpretation of cooling curve of liquid iron sample. First arrest point, the liquidus is a temperature level is directly related to Carbon Equivalent. (online chemical testing for liquidmetal) CE = %C + %Si/3.

MICROSCOPE WITH IMAGE ANALYZER

Fully Automatic Structure analysis of castings like type-A structure in C.I. and nodularity, nodule counts in SG. Iron castings.

Our Customers

Our Customers

TESTING DETAILS

INCOMING RAW MATERIALS TESTING PROCESS

- PIG IRON– C, SI, MN., S, P, CU.

- LUSTER COAL – VM, ASH, FC-TESTING BY MUFFEL FURNACE

- SCRAP – C, SI, MN., S, P, CU... BENTONITE POWDER– SWELLING CAPACITY, MB

- VALUE, GCS, WTS ...

- CARBON, SULPHUR TESTING BY USE OF CARBON- SULPHUR APPRATUS

- SI., MN, IS TESTING USING CHEMICAL SOLUTIONS.

MANUFACTURING TESTING PROCESS

- FULLY EQUIPED INHOUSE SAND TESTING LAB WHICH HAS MOISTURE TESTER, GCS, WTS, PERMEABILITY TESTER AND MANY MORE.

- MOISTURE TESTER- TO TEST MOISTURE OF SAND.

- GCS-TO CHECK GREEN SHEAR STRENGTH OF MOLDIN SAND.

- VM, LOI TESTING BY MUFFEL FURNACE AND OVEN.

- ACTIVE CLAY SAND TEST BY MB TEST.

CASTING INSPECTION PROCESS

- ROCKWELL HARDNESS TESTER TO CHECK HARDNESS OF CASTING.

- VERNICIER CALIPER, HEIGHT GUAGE, MICROMETER TO CHECK DIMENTIONS OF CASTINGS.

- MPI (CRACK DETECTION)

- UTM(TO CHECK TENSILE, ELONGATION)

- FULLY AUTOMISED MICROSCOPE WITH IMAGE ANALYSER.

MELTING TESTING PROCESS

- PYROMETER- TO CHECK TEMPRATURE OF MOLTEN METAL

- AMETEC LASER GUN TO CHECK INSTANT TEMPRATURE RESULT.

- CEMETER-TOCHECKC, SI., OF MOLTEN METAL.

- SPECTROMETER TO TEST 28 ELEMENTS IN METAL.

Have questions? Get in touch!

Reach out to our expert team for inquiries, quotes, and collaboration opportunities