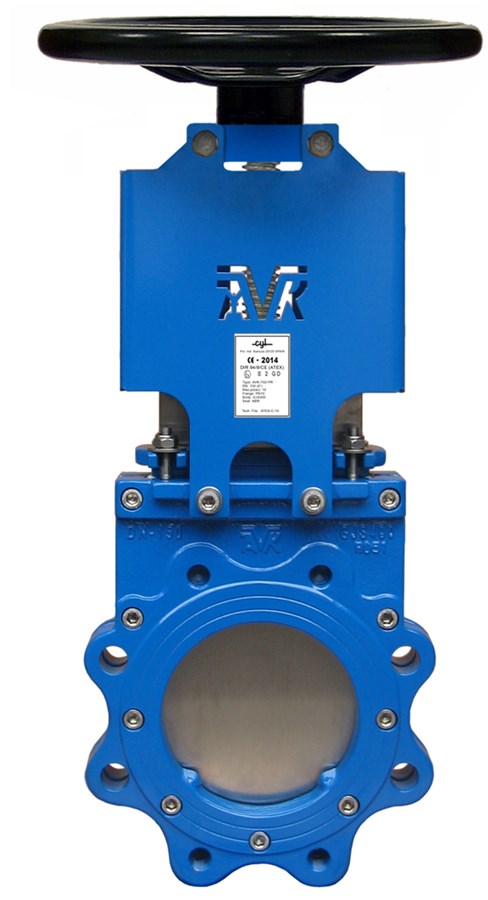

Knife Gate Valve

What is a Knife Gate Valve?

A knife gate valve is built for industrial use to manage thick and abrasive types of liquids by cutting through them with a sharp-edged blade. Frequently, a phosphoric acid machine is applied in wastewater treatment, mining, and pulp and paper. The operation of the valve starts with a blade being placed in front of the opening to close it and then lifted to open it for the movement of fluid. The valve is designed for slurry and solid-filled flows because it is self-cleaning and lets little pressure through.

Ductile Iron Knife Gate Valve Features

The durability and ability to withstand abuse from regular use make these valves very popular.

- High-Powered Body: The build of a ductile iron knife gate valve enables it to resist both high pressure and strong mechanical forces.

- Corrosion Resistance: The materials used in these valves help them stand up to rust and chemicals, granting them usefulness over time.

- Smooth Operation: With the design, the iron knife gate valve can open and close easily, even when the valve is facing higher pressure.

- Compact Structure: You can install a ductile iron knife gate valve in small spots since it has a compact design.

- Leak-Proof Sealing: The valve is very reliable and prevents fluid from leaking, especially when things are difficult.

Specifications of Knife Gate Valve

Knife gate valves are designed with many specifications for use in different industries. Engineers compare knife gate valve advantages and disadvantages with other valve types for better selection.

- Material Options: Even though ductile iron casting is most commonly used, stainless steel and cast iron are alternatives.

- Pressure Ratings: Waiting on application, these valves may be designed for low to medium pressure levels.

- Sizes and End Connections: The size and type of end connection for a knife gate valve can be flanged, lugged, or in a wafer style.

- Temperature Tolerance: These materials function in diverse settings because they work well at many temperatures.

Applications of Knife Gate Valve

Such valves have many applications in various industries because they can cut and seal items.

Wastewater Treatment Plants

Sludge and slurry are handled efficiently in sewage and treatment processes with knife gate valves.

Mining and Minerals

They are the best valves for slurry transport lines in mining processes.

Pulp and Paper Industry

The design of the ductile iron knife gate valve makes it great for processing fibrous pulp in paper mills.

Food and Beverage

It is used in places where thick or semi-solid products need to be regulated.

Trusted Knife Gate Valve Manufacturers, Suppliers in India

Selecting appropriate knife gate valve suppliers and manufacturers guarantees they work well and are safe.

Reliable and proven products are available from Knife gate valve manufacturers who have worked in the industry for several years.

Well-known knife gate valve suppliers follow the standards set by both national and worldwide organizations.

- Custom valves are offered by many knife gate valve manufacturers.

Reliable suppliers ensure fast delivery all over India.

FAQs

This valve works well with slurry, thick fluids, and solids.

Knife gate valves handle solids; butterfly valve works better with clean liquids.

The expected pressure rating is usually somewhere between 2 and 10 bar for different sizes and materials.

KGV stands for Knife Gate Valve.

A knife gate valve does not increase pressure; it regulates or blocks flow to maintain system control.