Rotary Valve Manufacturers

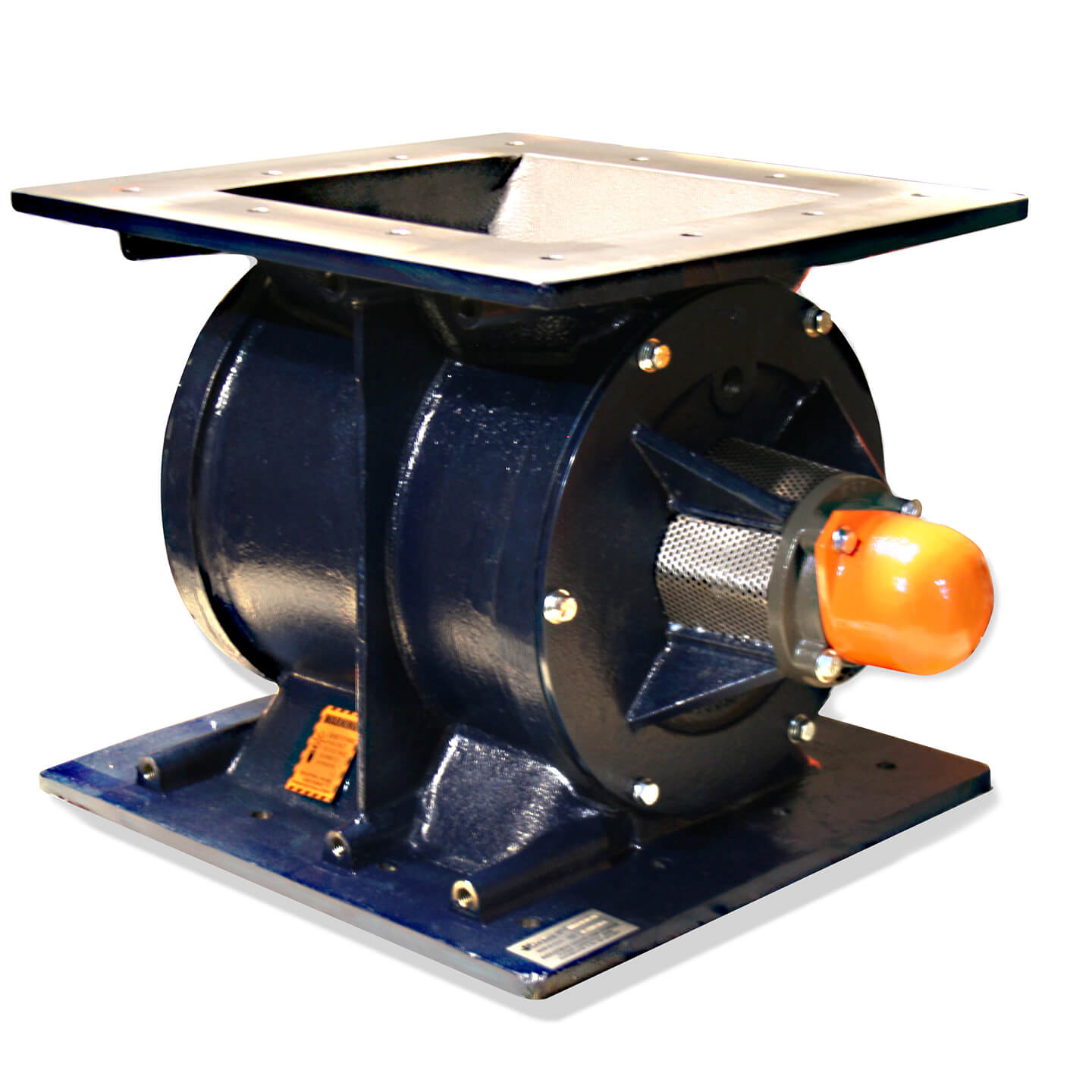

RM Technocast is proud to be leading Rotary Valve manufacturers in India. As the reputed manufacturer and supplier in India, we provide you with different types of Rotary Valves, including industrial air lock valves, drop through Rotary Valves, Rotary airlock Valves, etc. Each Valve manufactured by our team is well-designed to meet the safety standards of industrial applications and ensure reliable operation and efficient material handling.

What is a Rotary Valve?

Rotary Valves are the essential components used in several industrial applications, including food processing, chemical processing, pharmaceutical manufacturing, etc. These valves control the flow of materials from one point to another.

Key Features of Rotary Valve

Here are the key features and characteristics of the rotary valve

Our Rotary Valves ensure controlled material discharge and smooth flow

Our Rotary Valve manufacturers use quality materials to manufacture these valves and deliver long-lasting performance.

These Rotary Valve prevents material leakage and contamination

You can buy the Valve in different sizes, materials, and configurations, and fits from our rotary valve suppliers that fit your industrial needs.

Our Rotary Valves are suitable to use for handling abrasive, corrosive, and high-temperature materials.

Buy the RM Technocast’s Rotary Valve for quick disassembly and hassle-free maintenance benefits.

Get smooth operation at minimal power consumption by buying Rotary Valves from our rotary valve exporters.

Rotary Valve Technical Specifications

Here are the technical specifications of our Rotary Valve body

Parameter | Value |

Design Type | Round & Square |

RAV Size | 150 mm NB (6 inches) |

Material (MOC) | Grey Iron / Ductile Iron |

Rotor (MOC) | MS Fabricated (Vanes = 08 Nos.) |

Drive (Gear – Motor) | 0.5 HP to 5 HP |

Application | Fly Ash, Cement, Clinker, Sponge, Iron, Coal, Dust, etc |

Product Weight Range | Few Grams to 100 kg |

Rotary Valve Body: Material & Design

Here are the materials we use in our rotary valve body and design aspects

Speed

The typical speed of our Rotary Valve ranges between 5 and 50 revolutions per minute (RPM)

Material

Our rotary valve exporters use high-quality materials like grey iron, ductile iron, stainless steel, cast iron, carbon steel, and aluminum in these Rotary Valves

Design

Our Rotary Valves are made with a fixed or adjustable rotor on the basis of your requirements. If we talk about design elements, it consists of a number of vanes, a sealing mechanism, and a manual or automatic drive.

FAQs

The Rotary Valves are used to control the flow of bulk material and maintain a pressure differential between two areas.

The purpose of our Rotary Valves is to regulate the flow of material and maintain an airlock to prevent air loss.

Our Rotary Valves work by using a rotating rotor that has chambers or pockets. Its design controls material flow and reduces air leakage.

You should use rotary valves to ensure flow control, maintain system pressure, and handle the delicate or abrasive materials efficiently.

Our rotary valves are made with high-quality materials, like grey iron, ductile iron, carbon steel, stainless steel, cast iron, and aluminum.

The key benefits of our Rotary Valves are that they handle a wide range of bulk materials, reduce air loss, are versatile, have robust construction, are easy to maintain and clean.