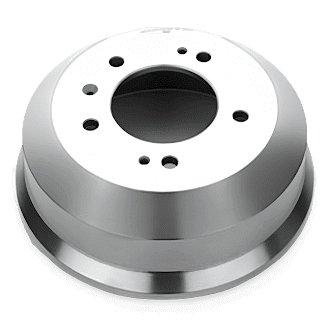

Brake Drum

Product Overview

One such part that plays a critical role in a significant number of braking systems, especially in commercial vehicles, heavy-duty trucks, and some passenger cars is a Car Brake Drum. A Brake Drum exporter has designed it as a safety and performance brake that offers good braking by transforming kinetic energy into heat by friction.

How Do Brake Drums Work?

A Brake Drum is used to generate friction where the brake shoes touch its inner face. This friction causes the rotation of the wheel to be slowed down which practically causes the vehicle to come to a standstill.

The braking process is smooth and reliable since it converts the kinetic energy into heat. Brake drums are well designed to provide even heat dissipation as well as performance.

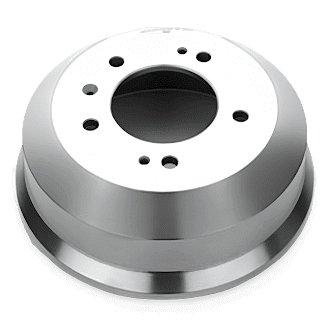

Product Specifications

RM Technocast produces brake drums through high quality casting. Key specifications include:

Specification | Details |

Material Used | High-grade cast iron / alloys |

Weight | 5kg – 40kg |

Diameter | 180 mm – 420 mm (varies by vehicle type) |

Manufacturing Process | Precision casting for accuracy |

Durability | Withstands high temperature & stress |

Compatibility | Suitable for various passenger & commercial vehicles like buses, trucks |

Standards | Meets automotive industry quality benchmarks |

Features & Benefits of Brake Drum

Constructed using strong materials to last a long time.

not resistant to heat generated in braking.

It is designed to be used in bulk production and has low replacement cost.

Gives a good braking action in various driving situations.

Needs very little maintenance as opposed to certain braking options.

Applications of Brake Drum

Automobile

Used in buses, cars, trucks, and motorcycles.

High Machinery

Used in vehicles like cranes and other construction vehicles.

Machines in farming

Used in vehicles like loaders, tractors, and harvesters.

Aerospace and Defense

Used for high-performance braking in vehicles like Aircraft and other defense vehicles.

Applications of Brake Drum

Brake drums are popular in:

- Passenger cars

- Commercial trucks & buses

- Two-wheelers having rear drum brakes.

- As agricultural vehicles, Also, in industrial vehicles

Their flexibility has contributed to them being one of the most reliable braking systems in any industry.

Trusted Brake Drum Manufacturer, Supplier & Exporter

RM Technocast is a top Brake Drum manufacturer in Rajkot that focuses on precision-engineered automotive castings.

RM Technocast being a trusted Brake Drum Supplier and Exporter provides goods of the best quality and according to the international standards. The company offers long-lasting high performance Car Brake Drums that are certified with ISO 9001: 2015.

RM Technocast is a preferred partner by OEMs and international markets known to deliver with high quality standards and on time.

FAQs

A brake drum is a component that offers force to a set of brake shoes so that they can decelerate or halt the car.

Depending on use and maintenance, it varies but on average it is around 150,000-200,000 km.

This may prove advantageous in efficiency by cleaning the brake parts regularly, changing brake shoes punctually, inspecting the surface of the drum and so forth.

Weird and uncharacteristic noise, poor performance, vibrations during braking, and some cracks/wear on the drum.