Valve Casting Manufacturers

RM Technocast is the leading valve casting manufacturer in India and serves multiple industries. Being the trusted valve castings manufacturers, we are trusted by various customers and deliver value, reliability, quality, and high performance. Our extensive network of sales, service, and support provides you with prompt resolution and meets your industry. We are industry certified, and use the special tools and materials to produce the valve casting parts.

Being the top supplier and exporter of valve castings, RM Technocast provides high reliability and performance to your industry and runs businesses effectively. Our manufacturers team provides great dedication to continuous innovation.

Different Valve Casting Parts We Offer

At RM Technocast, we manufacture different types of valve casting parts.

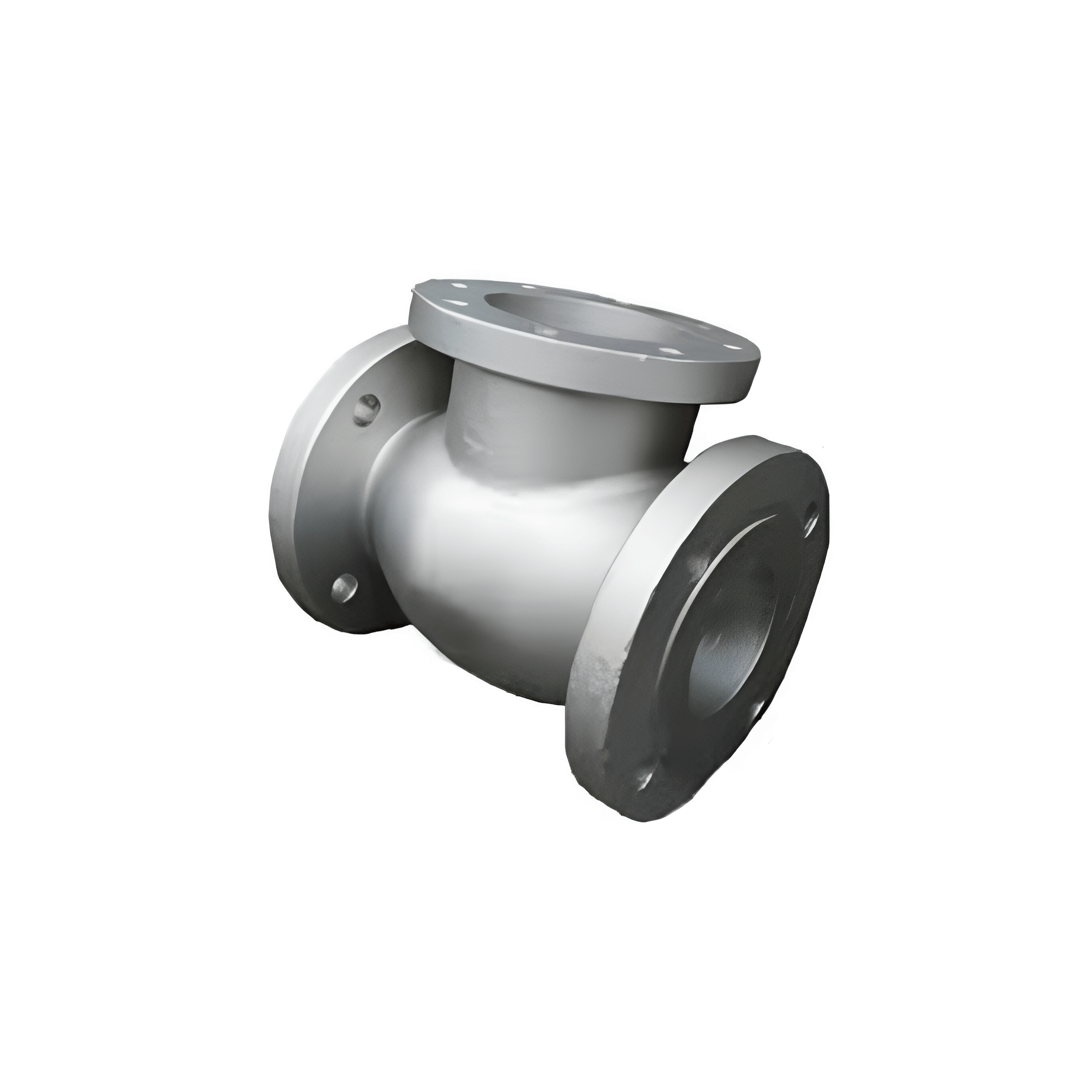

Valve Body

We also manufacture valve bodies. Our valve body is considered the primary pressure-containing component of the valve. We designed and supplied the precision engineered valve bodies that are made up of the high grade alloys. Our casting parts undergo quality testing, to deliver you durable and corrosion resistance components.

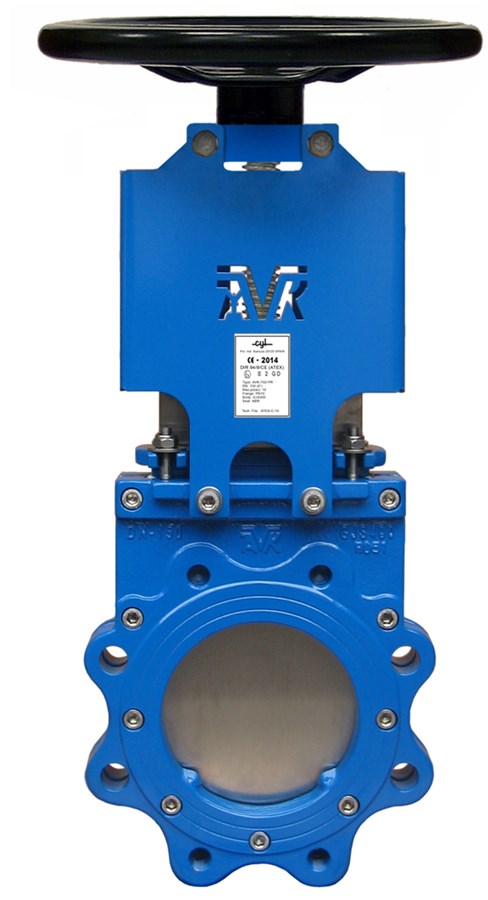

Butterfly Valve

Another type of valves we manufacture are Butterfly valves. It is used in manufacturing sector. Along with manufacturing industry, it is also used in oil and gas production, water treatment, power generation, and food and beverage processing.

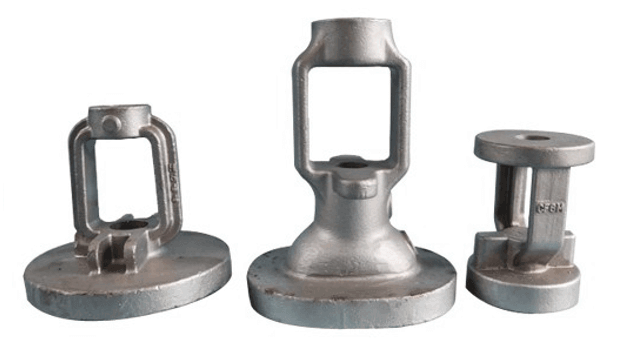

Handwheel

The handwheel valves are essential for manual valve operation. We manufacture strong handwheel casting parts for torque operation, easy handling, and long service life.

Steam Trap Valve

Our Steam Trap Valves are well-designed to ensure efficient and reliable operation. We provide you different types of steam traps, including mechanical, thermodynamic, and thermostatic steam traps. Each type of steam trap is suitable for industrial use and works under strict operating conditions.

Ball Valve Body

The Ball Valve Body is a crucial component in ball valves. It houses internal parts, like stem, balls and seats. These components are manufactured with advanced casting methods such as sand casting and investments casting. Our Ball Valve Body Suppliers use high quality materials like SS, Carbon steel, and alloy to supply these durable components.

Butterfly Valve Body

The Butterfly Valve Body is a high-quality and performance product that is designed for various industries. These values are well designed to provide optimal control on fluid flow in several applications. The Butterfly Valve Body parts are used in chemical processing, water treatment, HVAC systems, food and beverage industries. Our Butterfly Valve Body suppliers have high durability and corrosion resistance, that make it suitable for several environments and operating conditions.

Check Valve Body

A valve system relies on the check valve body to direct fluid flow in just one direction. It works with the internal system to prevent liquids or gases from going backwards. These are fitted in pipelines, industrial sites, and in various kinds of fluid-handling devices.

Control Valve Body

The main part of a control valve system that influences fluid flow is the control valve body. It provides protection for the inner parts that are in charge of controlling pressure, rate of flow, and layout in pipelines.Constructed for accuracy, it can control both automated and manual fluids such as liquids, gases, or steam inside industrial places.

Knife Gate Valve

A knife gate valve is built for industrial use to manage thick and abrasive types of liquids by cutting through them with a sharp-edged blade. Frequently, a phosphoric acid machine is applied in wastewater treatment, mining, and pulp and paper. The operation of the valve starts with a blade being placed in front of the opening to close it and then lifted to open it for the movement of fluid. The valve is designed for slurry and solid-filled flows because it is self-cleaning and lets little pressure through.

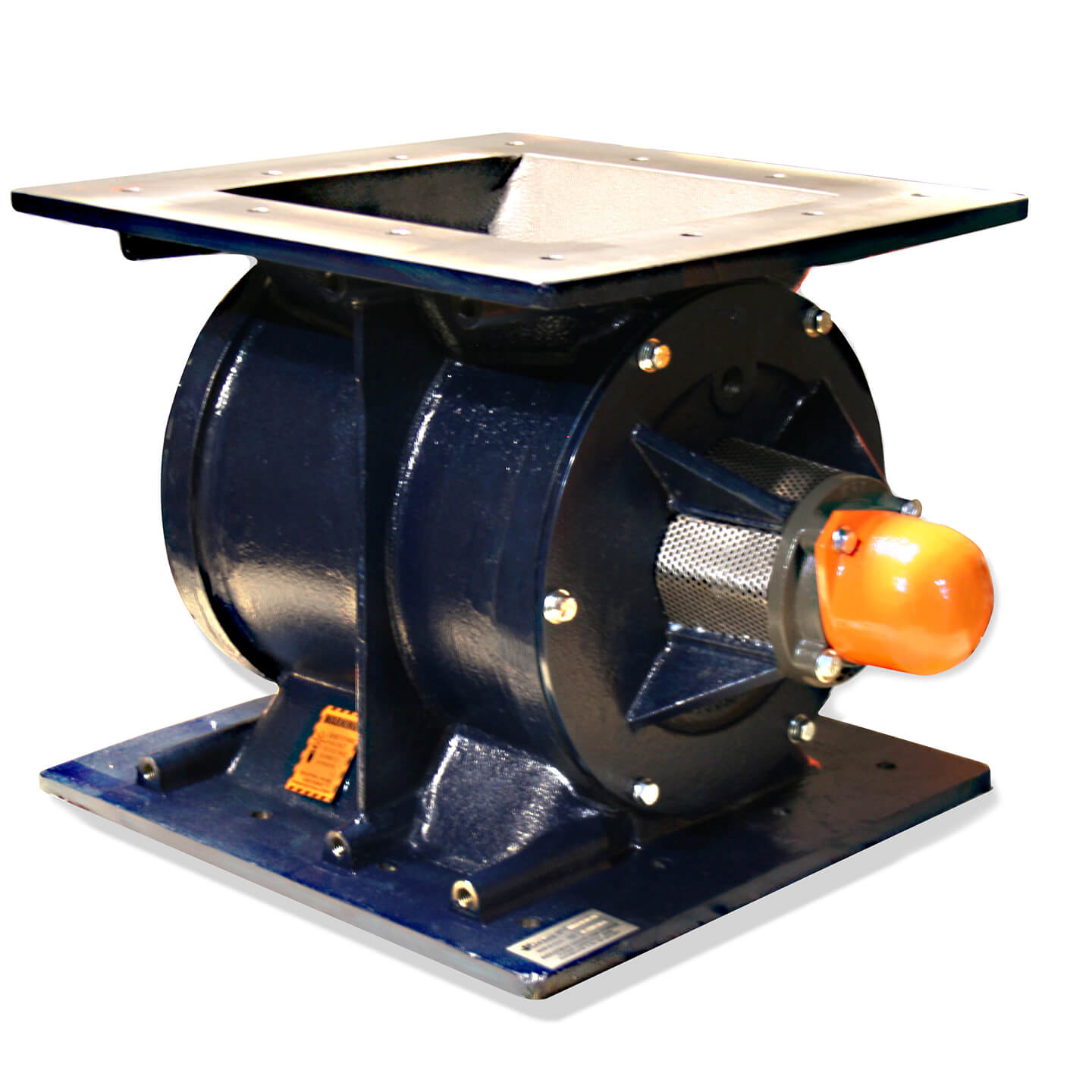

Rotary Valve

Rotary Valves are the essential components used in several industrial applications, including food processing, chemical processing, pharmaceutical manufacturing, etc. These valves control the flow of materials from one point to another.

Valve Spindle

Valve Spindles are the components used to control the flow of air and exhaust gases. It can be either circular or cylindrical cross sections. These components are manufactured from medium carbon construction steel. A Valve Stem or Spindle consists of a valve disc, core body, and annular valve seat.

Valve Bonnet

Valve Bonnet is the important component in several valve systems. It plays a crucial role to ensure proper functioning and safety during industrial processes. It is called a valve cap or valve cover. Valve bonnet or yoke is also referred to as protective housing that encloses the internal working of the valve.

What Are Valve Castings?

The Valve casting are valve parts made with metal casting process. These valves are works by control flow of liquids, gases, and slurries by piping systems. Valve casting is perfect manufacturing solutions to produce the valve parts, such as the disc, bonnets, valve bodies, seats, plugs, and other components.

Applications of Valve Castings in Various Industries

Our valve casting parts are versatile and used in different industries. It is because of its reliability, strength, and versatility. Here are various applications of valves castings parts

Water Treatment

The valve casting parts we manufacture are used in water treatment plans, and regulate water flow and chemicals flow. It is corrosion-resistant casting that ensures consistent performance and durability in harsh water environments.

Oil and Gas Industry

Our valve casting parts are also used in the oil and gas industry. Our valves casting parts are used to control flow of crude oil, fluids and natural gas. It has ability to withstand high pressure and corrosive environments, that make it crucial in different industries.

Chemical Industry

Our valves casting is perfect for industrial use, especially in chemical industry. It helps to regulate flow of gases and liquids. Its high resistance and corrosion resistance properties make it suitable to use in chemical processing plants.

Automotive Industry

In the automotive industry, our valve casting plays a crucial role to regulate gas flow and fluid. These castings will deliver the performance and efficiency of vehicles, especially in high-performance vehicles.

Power Generation

The valve castings are made with cast iron material, and used widely in power plants. It plays a vital role to regulate water and steam flow. Its wear resistance and thermal stability properties ensure that it performs well under extreme pressure and temperature.

Food and Beverage Industry

Our valve casting parts are used in the food and beverage industry. We manufacture the valve casting components by using the sand casting method and provide precise control of fluid flow.

Benefits of Valve Casting for Industrial Applications

The advantages of our Valve Casting parts are given below. The high durability, precision, corrosion resistance, and following benefits make it suitable for industrial applications.

The Valve Casting parts our valve casting parts suppliers use withstand high temperatures and pressure. It becomes suitable for use in harsh environments and delivers high performance.

Our valve casting manufacturers manufacture the components by using quality materials. Our components are made with materials like cast iron, SS and bronze, and make it corrosion resistant. It makes these components to use in applications that deal with corrosive gases and fluids.

Our valve castings parts are manufactured with high dimensional accuracy. It ensures a precise fit and functioning in complex industries.

Another benefit of our Valve Casting is that it is strong and handles high-stress conditions. It makes it suitable for use in oil and gas industries, power generation, and chemical processing.

The Valve Casting can handle temperature resistances and become suitable for high-temperature applications like chemical processing and power plants.

The industries that require the precise flow regulation, can benefit from valve casting parts. It is used in various industries, like oil and gas and water treatment, due to its flow control ability.

Materials Used in Valve Castings

Our valve casting parts manufacturers at RM Technocast use different types of materials to manufacture Valve Casting. Here are the quality materials we use

Our manufacturers use stainless steel material to manufacture valve casting parts. This material provides good strength , ductility and excellent corrosion resistance, and become suitable in corrosive environments.

We also use carbon steel material to manufacture valve casting parts. It delivers high resistance and strength. It is an easily machinable and weldable material to use in casting manufacturing.

Our valve casting parts are also made with alloy steel. It ensures pressure and temperature resistance and provides good toughness.

The industry that demands good vibration dampening and excellent wear resistance in valve castings must choose components made with grey cast iron.

We also use the ductile iron to manufacture Valve Casting parts. It delivers higher ductility and strength than grey cast iron.

Leading Valve Casting Manufacturers, Suppliers & Exporters in India

RM Technocast is a well-established company of Valve Casting in India. We manufacture quality Valve Casting and deliver high performance and strength in your industry. We have years of experience in the casting process and use cutting-edge technology to create sustainable Valve Casting components. Here what makes us the leading valve casting manufacturers and suppliers in India

Expertise

We have years of experience and knowledge to manufacture high-quality Valve Casting parts.

Advanced Technology

Our valve casting parts suppliers use state-of-the-art manufacturing techniques to deliver high reliability and precision.

High-quality materials

Our Valve Casting parts are made with durable materials like cast iron, stainless steel, and bronze.

Trusted Partner

RM Technocast is the trusted partner of Valve Casting and provides you with various types of components for different industries. We supply the casting components in water treatment, oil and gas and power generation industry.

FAQs

The most common materials used in Valve Casting are cast iron, SS, carbon steel, and special alloys. Our valve casting parts manufacturers pick the quality materials wisely on the basis of your industry needs, performance preferences, and other properties.

At RM Technocast, we use metals like grey iron, carbon steel, stainless steel, brass, ductile iron, and bronze to manufacture casting parts.

The timeline our valve casting parts manufacturers take depends on volume of order and complexity. It ranges from 2 to 6 weeks, including making, casting, machining, and testing

Our valve casting parts are used widely by different industries. These parts are used in water treatment, chemical processing, power generation, oil and gas, HVAC, etc, and manage gas and liquid flow in crucial applications.

Choosing RM Technocast is beneficial for valve castings parts, because it delivers high strength, performance, durability and temperature resistant properties. Whether you require the valve castings components for high pressure or corrosive environments, we serve you. Our every component adheres to strict quality methods and delivers you quality products.